SPC 40-10

Equipped with a hinged lid featuring an integrated viewing window, this compact system offers the optimal solution for small spray tools.

- Small spray tools

W 800 x D 700 x H 350 mm - System pump with 160 l/min

- Stationary

- Manual

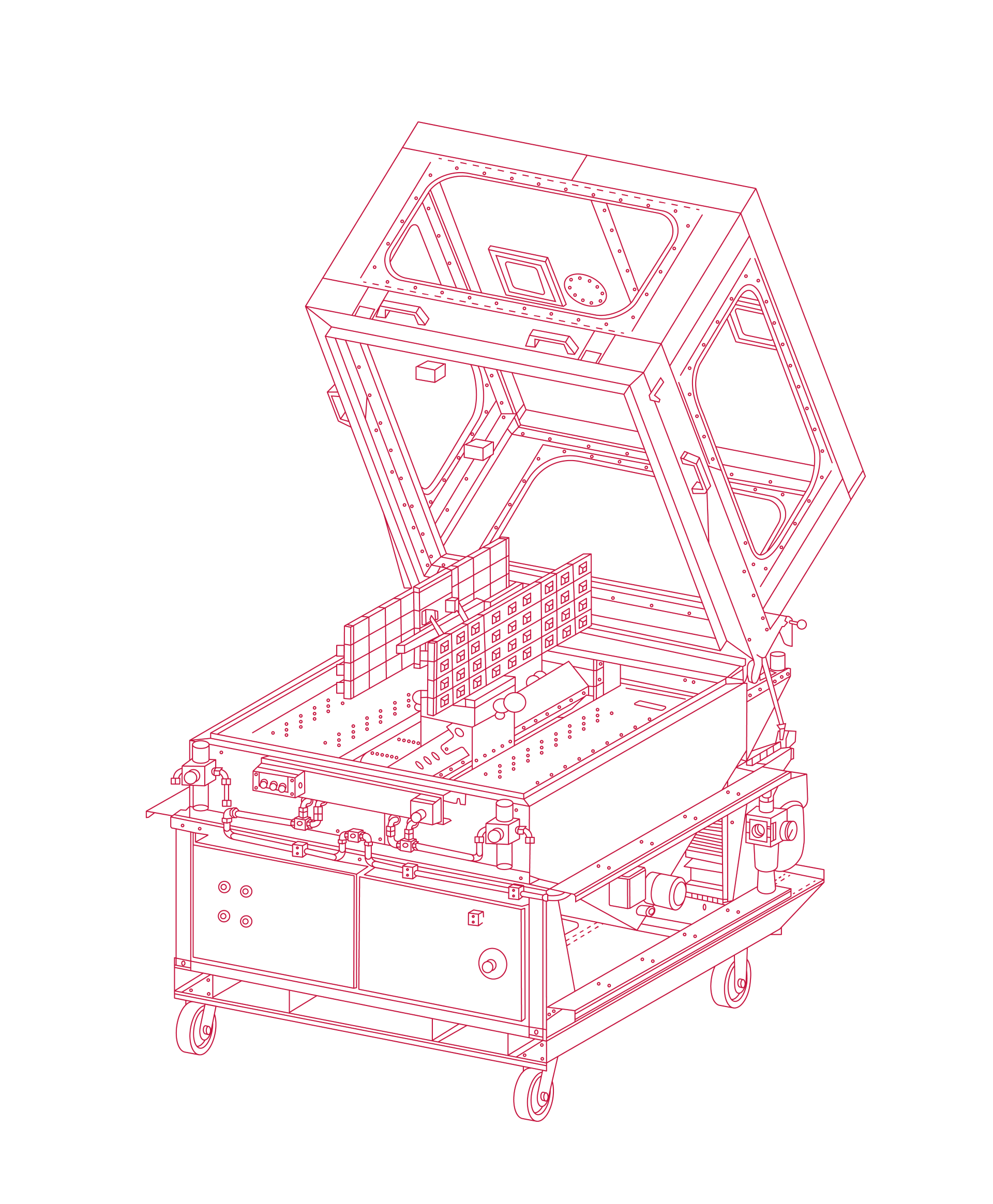

SPC 40-12

For cleaning medium-sized spray tools, these mobile systems are equipped with a swivel hood with integrated all-around viewing windows.

- Medium spray tools

W 1,000 x D 1,000 x H 800 mm - System pump with 160 l/min

- Mobile

- Manual / semi-automatic / automatic

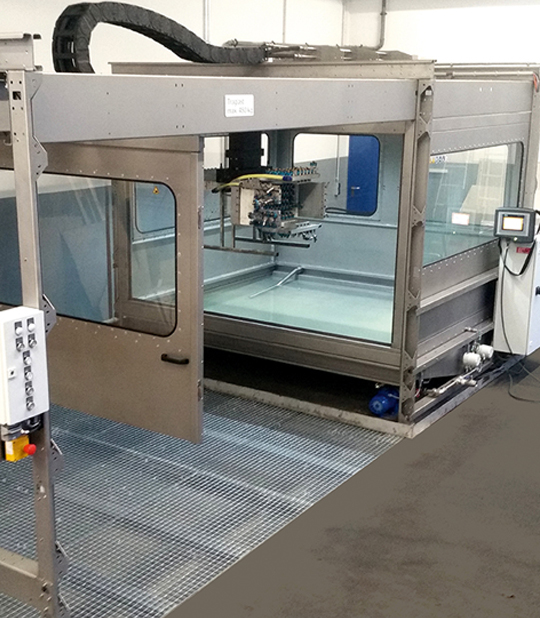

SPC 40-22

For large and heavy spray tools, this cleaning system is equipped with an integrated linear unit. A lifting table significantly simplifies the connection of the spray tools.

- Large spray tools

W 2,500 x D 2,500 x H 1,500 mm - System pump with 300 l/min

- Stationary

- Manual / semi-automatic / automatic